Seamless integration

Data Drives Productivity with Blade Inspect

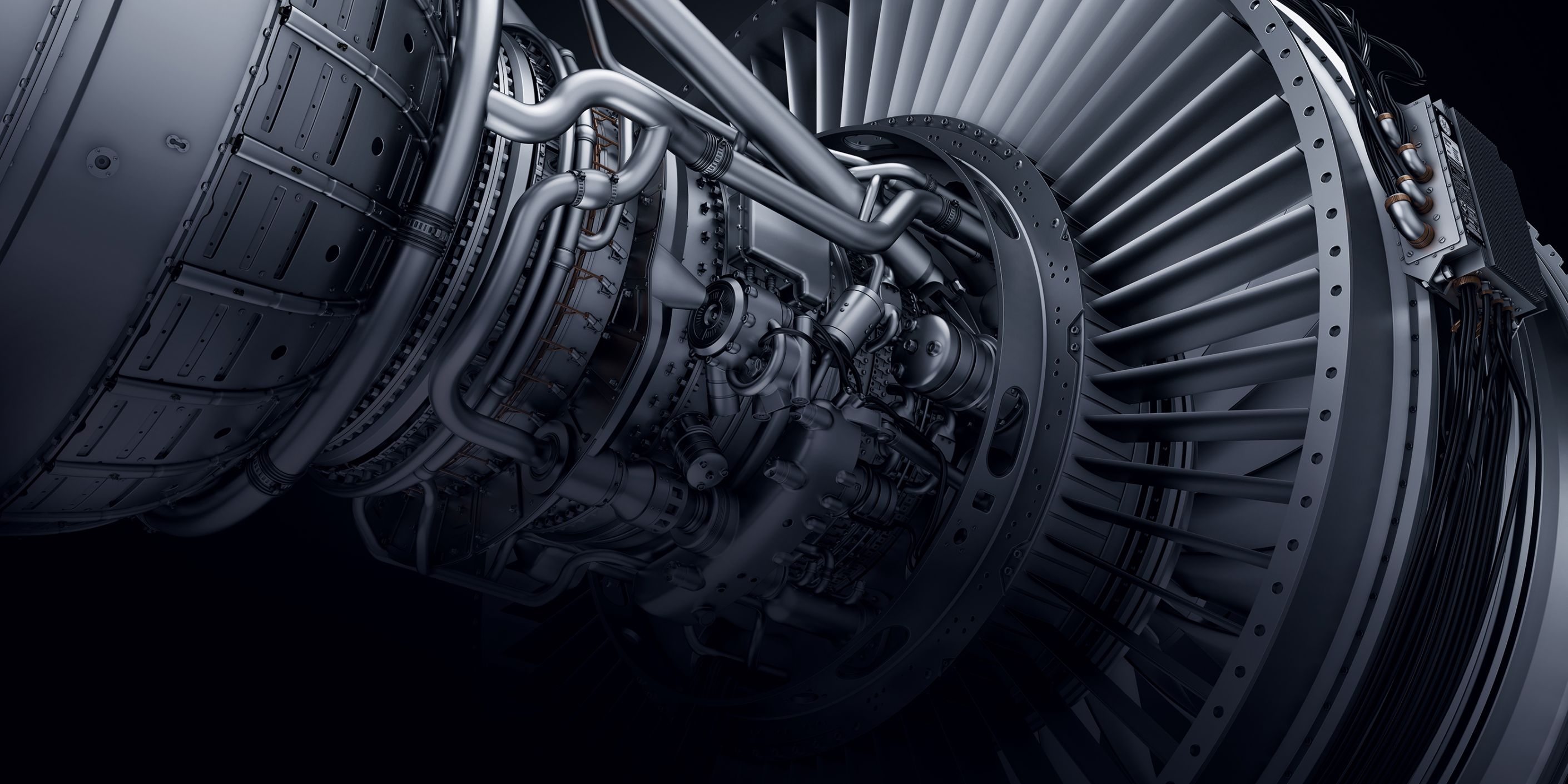

Cutting-edge technology in the sky: Modern aircraft are constantly exposed to environmental conditions, subjected to severe stress and used to transport passengers and air cargo. No wonder the aerospace industry is one of the most demanding of all. It relies on the highest precision, especially in manufacturing and quality control. Inspecting components in the aviation industry requires expertise and experience – this is where our Blade Inspect software comes to save you time and money.

Blade Inspect is our solution for airfoils, particularly for the analysis of blades, blisks and guide vanes in gas turbines. It is easy to use and has unique functionalities that are tailor-made for the requirements of the aerospace industry. The powerful analysis and inspection software works with tactile, optical and CT data.

Airfoil analysis techniques are well established and have been similar for decades. Usually, there is an airfoil alignment principle, followed by multiple sectional evaluations at radial heights for key characteristics such as chord, edge radii/circles, maximum thickness and the profile form and position. The standards are relied upon as a means of checking the conformance of the part to a drawing or specification. Today, these values are used to evaluate the performance of the part, which is well established but brings some uncertainties and assumptions when compared to design analysis.

Blade Inspect supports these airfoil analysis techniques with a dedicated workspace, in which specific standard functions are compiled for easier use. A guided workflow enables the setup of inspection for most scenarios. Inspections of a section can be carried out in seconds. It is very easy to repeat measurements and evaluations with project templates that can be used to copy and paste inspections to new parts. Besides these basic techniques, the real value of the software comes from its advanced functionalities.

With Blade Inspect, we close the gap between design and manufacturing. We have been driven by adding value from data, for example, giving more functional feedback to the design department or downstream processes like assembly. For this, the software offers easy visualizations of results to enable communication and decision-making based on data. We have built a software solution that is not just made to meet the requirements of today but also for designing the future of airfoil measurement and inspection.

With the current software version of Blade Inspect, we have reached a seamless integration with our CMMs. The probe path and measurement can be executed using the long-established ZEISS CALYPSO software. The inspection and reporting of the analysis are then carried out using Blade Inspect – thus making Blade Inspect our standard solution for airfoils – independently of the hardware in use.

Blade Inspect is scalable to meet the needs of any industry that uses and produces airfoils. It could be a wind turbine, hydro-electric impeller or the propeller of a ship. The ZEISS solution is tried, tested and focused on providing the right solution to the challenges of the future.

3D Throat Area

As an industry first, Blade Inspect brings the analysis of throat area into the digital era. Up to now, the inspection of the most critical part of a turbine regarding design and efficiency was very time-consuming, and the result was just an approximation based on discrete measurements on predefined positions.

The new Throat Area feature 3D Throat Area computes the 3D minimum surface between two airfoils. Using minimum surface calculations, the geometric 3D throat area is measured and reported no matter if it is a partial surface or a fully enclosed passage. This is the best method available today by any measurement software to correlate between geometric and aerodynamic means.

Virtual Balancing

With 3D data, in form of a digital twin, it is possible to apply physics in a smart way by calculating a centroid of blades and derive the imbalance of each. Once calculated for a set of blades, the order by which they should be assembled into the disc to cause the minimum imbalance can be determined. All that is required is the measured data in a simple user interface. This has huge advantages in terms of time saving for the assembly processes.

Additionally, this offers further uses of the digital twin in cases where cases where blades are already being measured at the end of the process.