Highly productive

Metrology Goes Inline

Automated systems in production

Due to the fast transformation in the manufacturing world – the electrification of the automotive industry and the realization of smart factories – more and more body shops are asking for fully integrated metrology systems in their lines. The digital transformation of inline metrology reduces the workload on measuring rooms while significantly increasing the number of measured parts.

When using inline systems, the shop floor staff can immediately respond to quality problems where they arise and control the production process proactively. The high-precision and absolute ZEISS inline solutions do not require any correlation and deliver reliable and conclusive measurement data for series production control.

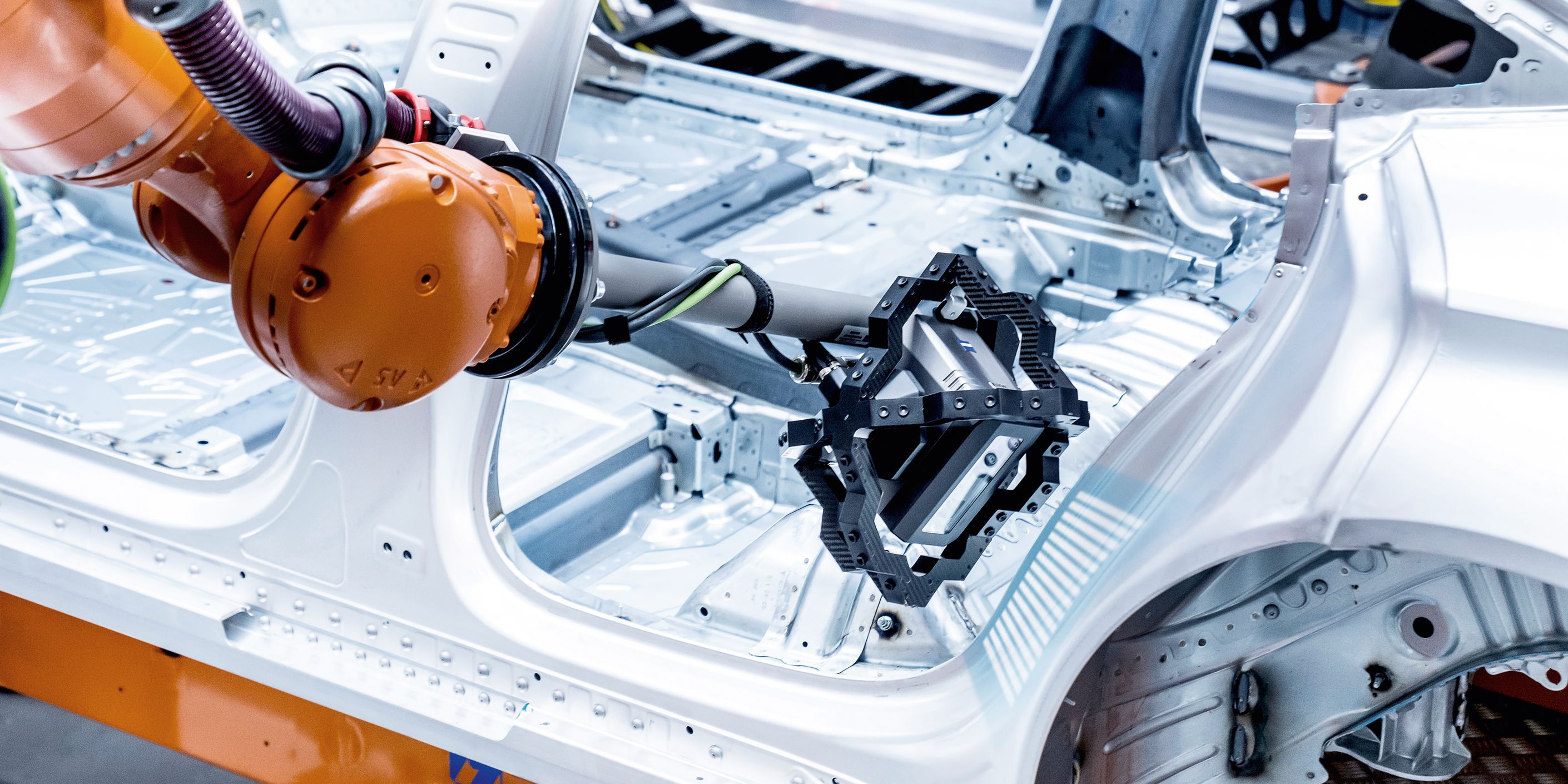

ZEISS AICell trace combines process monitoring and feature based inline metrology in one single cell.

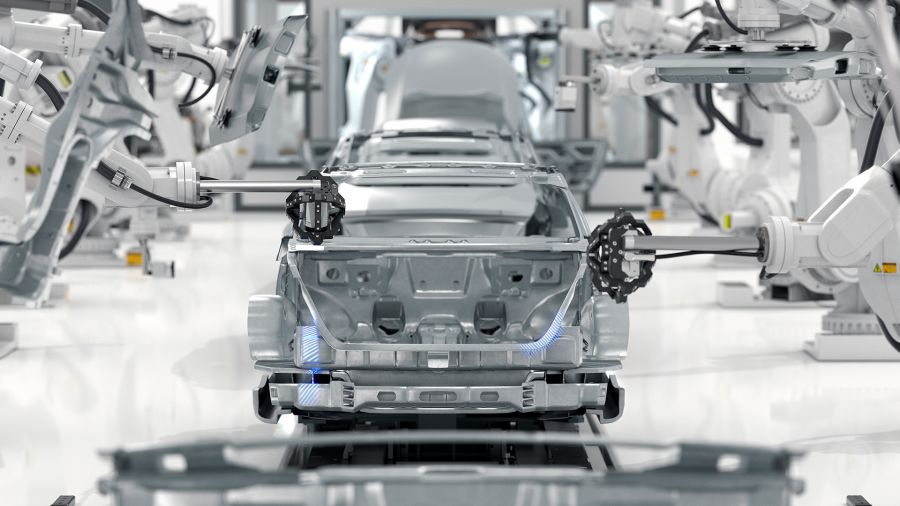

ATOS sensors digitize parts or even complete car bodies in the production line.

Process monitoring and featurebased inline metrology

The ZEISS AICell trace inline measuring system is helpful during production ramp-up and ensures process control directly in the production line. The highly accurate and fast ZEISS AIMax cloud 3D sensor captures very complex features on assemblies and bodies, e.g. bolts edges, holes, rivets or even the position of a welding nut behind sheet metal, in real time. The tracking technology used in the ZEISS AICell trace monitors the sensor position on the robotic arm with high precision, thus eliminating the need for complex correlation measurements in the measuring room. With this method, users will be able to obtain reliable, traceable measuring and inspection data from the first part produced during ramp-up onwards. Depending on the cycle time and the number of robots, the system captures up to 100 features per cycle. Rolling measurement and pause programs for analysis measurements also come with the features.

Full-field digitization of the body-in-white

After the features have been measured, robot-controlled ATOS sensors digitize the entire body-in-white from different perspectives with high precision and high detail resolution. Users can then extract process- and quality-related inspection characteristics for statistical evaluations by using the resulting absolute, correlation-free and traceable data. The sensors produce full-field 3D coordinates with every scan. As a result, you will see a complete digitization of the body-in-white, known as a geometric digital twin. Using the full-field measurement data, the 3D metrology software automatically derives the inspection feature plan and identifies deviations between the digital twin and the CAD data. The analysis clearly illustrates whether the chassis marriage is flush and without gaps. In the digital assembly, users can analyze the interaction of the outer skin with the hang-on parts before the actual assembly occurs.

Surface inspection measurement

ZEISS ABIS is the tailored solution for surface inspections in the press and body shop. The system inspects sheet metal panels quickly, easily and objectively throughout the complete process chain. A robot moves the optical 3D sensor over the parts to be inspected. The ABIS software recognizes surface defects and evaluates them according to the specification’s corporate standards. ZEISS ABIS easily inspects moving parts and is therefore ideally suited for inline use.