The new generation takes over

30 Years ZEISS PRISMO

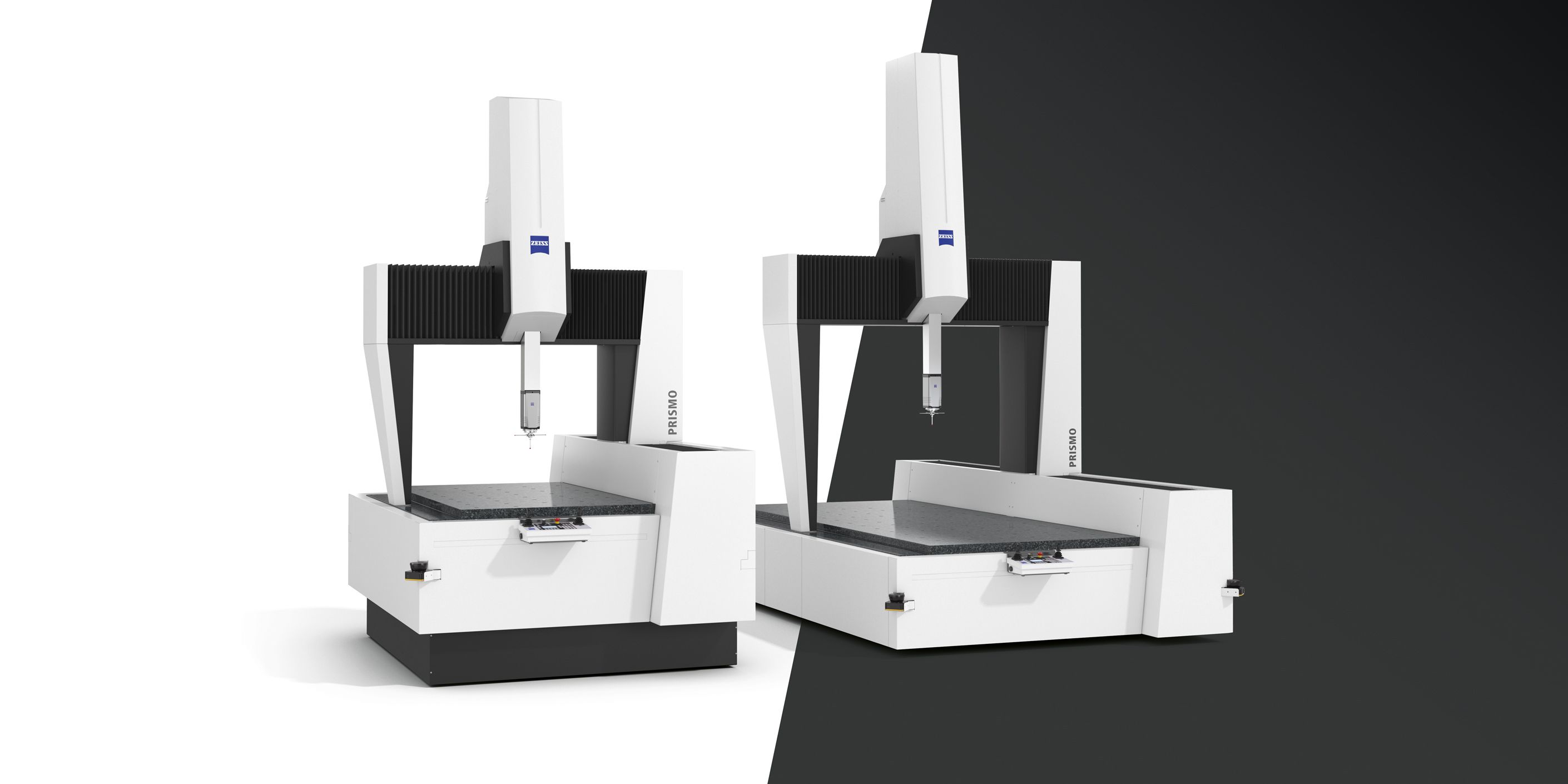

When it comes to precision, the coordinate measuring machines of the ZEISS PRISMO Family have always been leading at the cutting edge for more than 30 years. Precision is the cornerstone of the production process and crucial for a reliable quality assurance. Precision is always progressing – as does the new generation of the ZEISS PRISMO Family. The machines combine speed, flexibility and productivity, reaching an unprecedented level and shaping the future of precision.

Leading CMM technology

30 years ago, the market launch of ZEISS PRISMO marked the beginning of a new era in metrology. In the decades that followed, we continued to improve the machine: Being one of the most fastest and accurate CMMs on the market, ZEISS PRISMO fully meets ISO quality standards and was the only device to be certified according to the DGUV (German Social Accident Insurance).

Today, the ZEISS PRISMO family has four model variants. ZEISS CALYPSO, the integrated measurement software, transforms transforms it into a reliable all-in-one-solution for numerous applications.

The future of precision

The next generation of the ZEISS PRISMO Family shines with many optimizations, such as sustainability and energy efficiency, ergonomic handling or user safety. The new, optional ZEISS CALYPSO software defines the rotary table axis within seconds for all models – thus ensuring even more precise measurements.

Plus, the ZEISS PRISMO 7/12/7 fortis model offers a new package tailored specifically to the requirements of the aerospace industry which speeds up measuring processes by up to 70% – while maintaining accuracy (see page 12 for more information).

New features

- Higher performance thanks to new scanning parameters

- 68% less power consumption thanks to control unit

- Virtually no power consumption in standby mode thanks to PowerSaver

- High degree of safety for operators

- Improved ergonomics and more storage space

- Easier manual loading

ZEISS TS – the new tailstock

The ZEISS TS tailstock can transform universal CMMs into shaft measuring machines. Shaft-like measurement objects such as gears, crankshafts, camshafts or screw compressors can be securely clamped between centers without suffering any deformations. As such, they are easily accessible and can be measured in a single clamping position. ZEISS TS is available in two z-sizes for various ZEISS PRISMO Family members.

25 YEARS OF ZEISS CALYPSO

Software is the crucial factor

ZEISS PRISMO unfolds its full potential in combination with ZEISS CALYPSO. The powerful universal software controls all ZEISS coordinate measuring machines from a single platform. It ensures fast, simple and reliable measurements of standard geometries and is suited for all applications in dimensional metrology. Thanks to its user-friendliness, operators can define inspection plans as well as measuring jobs and print detailed evaluations and reports at the click of a button – without any programming skills.

Add-ons for every need

ZEISS CALYPSO offers numerous add-ons which help users to tailor the software to their need. They can choose from 40 options to comply with special requirements and measuring jobs. The following examples illustrate how addons can save time and costs during inspections.

Remote programming

Users can generate complete CNC inspection plans on their remote workstation with the ZEISS CALYPSO planner add-on. Once completed, the measuring program can be opened and executed at any time with ZEISS CALYPSO. While planning jobs, the measuring machine is still operable so manufacturers can continue to use the measuring capacities.

Simulated measurement sequences

The ZEISS CALYPSO simulation add-on helps users to configure virtual stylus systems and much more. They can also load entire virtual stylus system change racks and integrate them into a simulation. The system then conducts risk-free analyses of automatically generated travel paths and adjusts them if necessary, thus preventing possible collisions.

Other options include free-form surface, curve and gear measurements. ZEISS CALYPSO and its optional features have become the gold standard on the metrology market over the past 25 years and are enhanced and expanded every year.

ZEISS CALYPSO

keeps setting new standards

ZEISS CALYPSO is the leading software in 3D coordinate measuring technology. It is the ideal solution for operating bridge-type measuring machines and makes for easier measuring result analyses. Christoph Grieser, Head of Global Software Sales, explains:

“CALYPSO is backed by a strong development team which develops and improves its functions and usability on an ongoing basis. With the 2023 release, we are yet again offering more than 80 new functions to our customers, which will continue to improve the performance of their measuring machines.”

ZEISS CALYPSO 2023, for instance, shines with an improved automated error analysis, optimized workflows for optical CMMs, improved usability and new ISO/ASME GPS evaluations.

“New customer specifications and their need for efficiency are always at the center of our developments," says Grieser. “ZEISS CALYPSO is the go-to software when it comes to analyzing geometric elements with coordinate measuring machines , and this is also a commitment to our customers: We innovatively drive software forward. At our What’s New event, you can learn more about the new features.”

Christoph Grieser

Head of Global Software Sales

ZEISS Industrial Quality Solutions