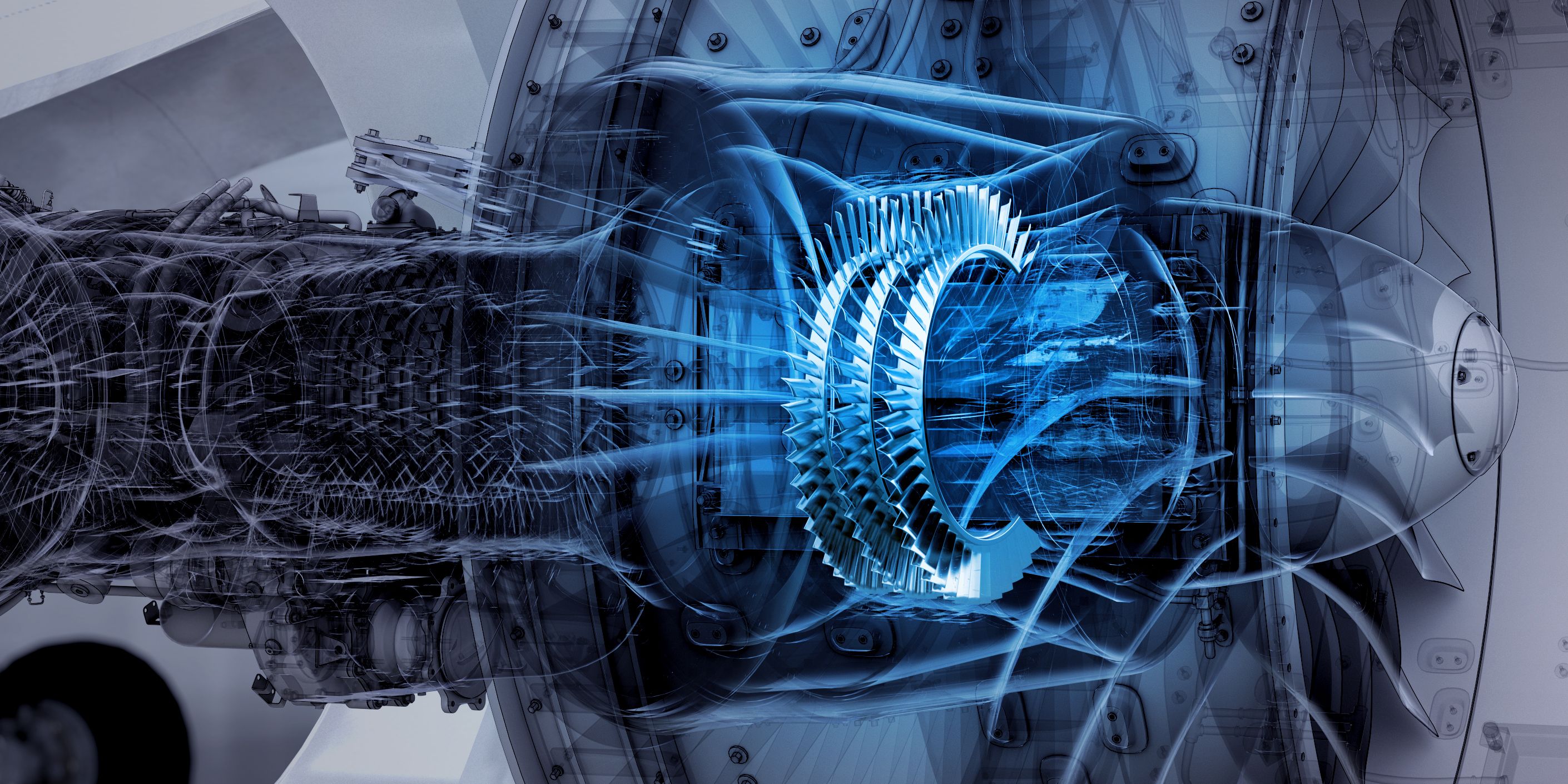

Next-level productivity in aerospace

Destination: Speed and Precision

New Aero CMM speeds up blisk and blade measurement by up to 70%

Quality inspection of engine components like blades and blisks is mandatory. Yet it is also expensive and time-consuming, accounting for some 20% of the total production cost and 25% of the total production time. New high-end metrology solutions from ZEISS speed up the measurement process by 70% without compromising on capability. Features like the new ZEISS CMM Acceleration Mode for Aerospace Applications promise significant savings for the sector at large.

The aero package for ZEISS PRISMO 7/12/7 fortis comprises a pair of options known as ZEISS VAST Rotary Table Axis (ZVRA) and ZEISS VAST Rotary Table (ZVR). ZVRA boosts accuracy by providing swift definition of the axis of the rotary table, while ZVR promotes faster movement of the rotary table and thus faster measurement.

The integrated measurement software ZEISS CALYPSO maximizes the hardware enhancements, making this a powerful all-in-one-solution for aerospace applications.

Operating requirements include the active scanning head ZEISS VAST gold, the new C99m controller, safety laser scanners, the RT-AB-600 rotary table and 315 mm or 400 mm face plates featuring a triple reference with 3 rolls. These new face plates harmonize the radial distances and the rotational pattern of the screw holes. ZEISS can also supply dedicated clamping systems and a customized automated loading system to support high productivity and reduced measuring times.

A league of its own

ZEISS CMM Acceleration Mode for Aerospace Applications delivers game-changing results for the aerospace sector. ZVRA and ZVR cut the time required to measure blades and blisks by 70% – all while achieving highly impressive data quality at such speeds. They also ensure repeatability and reproducibility within the tight tolerances of typical blade and blisk characteristics at maximum acceleration and maximum speed. And the dedicated application support package adds numerous customer-specific enhancements for extra productivity. Perfect for an industry that demands precision at pace.

The components of the ZEISS CMM Acceleration Mode package

ZEISS VAST Rotary Table Axis

The frequent definition of the rotary table axis is key for accurate measurement results. ZEISS VAST Rotary Table Axis (ZVRA) provides a new technology to define the axis by using continuous movement. With this, a frequent and fast definition of the rotary table axis

is ensured.

ZEISS VAST Rotary Table

ZEISS VAST Rotary Table (ZVR) enables a high-speed tactile scanning mode for rotary table measurements that speeds up the measurement process by up to 70%. As workpieces are measured on different levels, the higher scanning speed supported by ZVR results in significant efficiency gains for four-axis scanning operations.

Application support

ZEISS CMM Acceleration Mode for Aerospace Applications includes a dedicated application support package for even more customized deployment if needed. Services include the adjustment of detection parameters and machine parameters, such as the acceleration ramp of the individual X, Y, Z and RT axes if needed.