Large-scale metrology

An Optical Measuring Cell Beyond Compare

Powered by ZEISS ATOS LRX

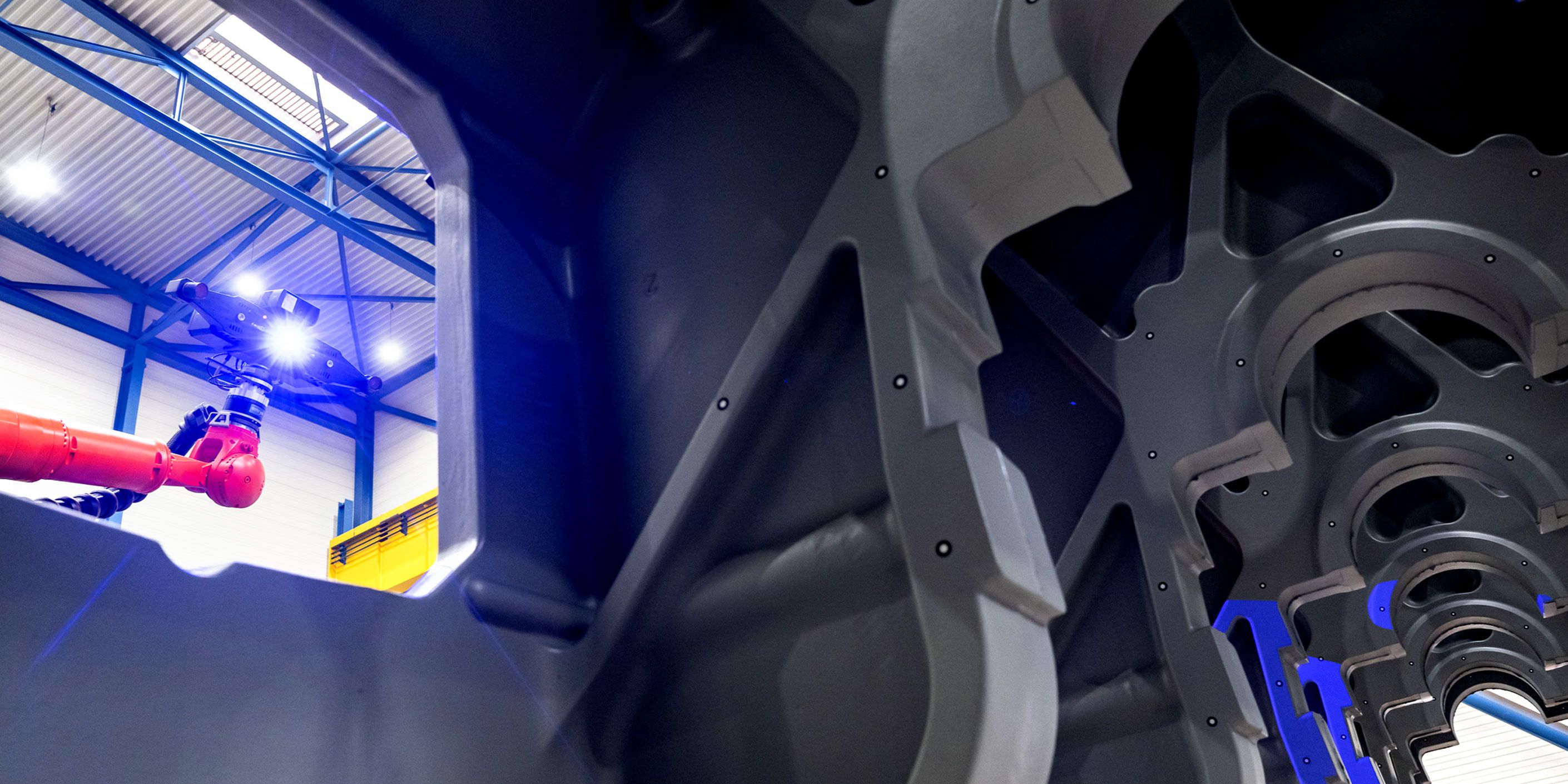

The German Siempelkamp Giesserei operates one of the world’s leading hand-molding foundries in Krefeld and manufactures giant components such as engine blocks for ships, metal forming presses and grinding pans. Together with ZEISS and the automation supplier a3Ds, the company has developed the world’s largest non-contact robot measuring cell for harsh environments.

Consistent digital quality control

This high-tech solution carries out fully automated inspections of components weighing up to 320 tons. The new ZEISS ATOS LRX sensor is at the heart of the system and has been specially developed for very large measuring fields. Thanks to a powerful laser light source, the 3D scanner delivers full-field data in no time – now for the first time for surfaces of up to four square meters.

Based on the measurement data, the software automatically visualizes full-field deviations between actual 3D coordinates and the CAD data. This information helps users to quickly identify, analyze and remedy quality problems. The foundry can now track the component geometry of all products from model to casting mold, all the way down to the finished casting by consistently applying digital methods.

Thanks to the full-field measurement data, the foundry has implemented a consistent digital quality control.

"We continue to drive our extensive digitalization strategy with this unique and highly innovative technology."