ZEISS eMobility Solutions

Fully Charged

The global market for new energy vehicles (NEVs) is growing at a tremendous pace: Electric vehicle sales are expected to reach more than USD 800 billion by 2027. The sharp increase in demand is putting more pressure on manufacturers and suppliers. Quality assurance, in particular, has to master new challenges and leads to bottlenecks, especially in fast-growing companies. Given its wide range of ZEISS eMobility Solutions and more than 1,000 customers worldwide in the NEV sector, ZEISS has become one of the most important industry partners.

The NEV revolution

NEVs are taking over the roads. Mostly cars but also two-wheelers, trucks, construction and agricultural machinery as well as other special vehicles use electric drives. In Europe alone, an estimated 185 million electric motors will be needed for NEV production by 2030. Batteries in particular are key in this mobility revolution. Not only do they determine output and range, they are also relevant for structure and thus safety in the entire vehicle.

Challenges in quality assurance

Industry has to tackle changing technologies and their impact on manufacturing processes due to the rapid development of e-mobility. The battery is a case in point: Highest precision is required right from the start so as to meet high efficiency, reliability and safety requirements in large-scale battery production. Quality criteria affect the choice of raw materials, the process of battery engineering as well as quality control of critical steps during electrode production down to the assembly of cells, modules and battery trays while meeting stringent tolerances.

ZEISS eMobility Solutions

ZEISS supports OEMs and suppliers around the globe by providing more than 50 solutions tailored to quality assurance in e-mobility. ZEISS continues to add new solutions to its wide range of imaging, analytical and metrological systems, e.g., in the field of inline inspections and software.

“When it comes to quality management, major OEMs and battery and electric motor suppliers rely on ZEISS solutions.”

Thanks to its global footprint and specialized teams in all regions, ZEISS has built a strong partnership with OEMs and suppliers in 22 countries, helping them improve their product quality while reducing costs. In addition to on-site support at the production line, ZEISS has also held more than 50 seminars and workshops to share technical know-how with its NEV partners.

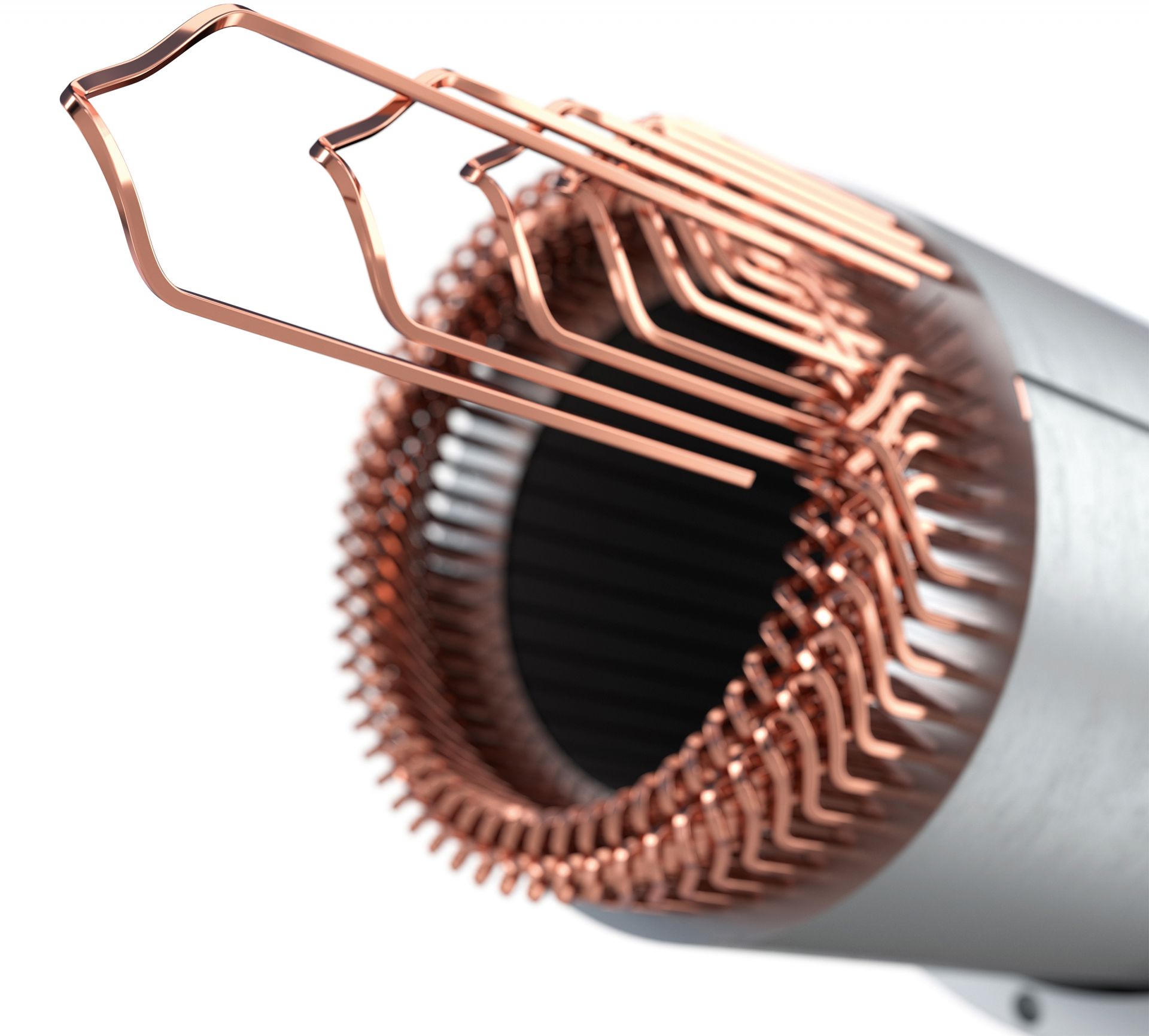

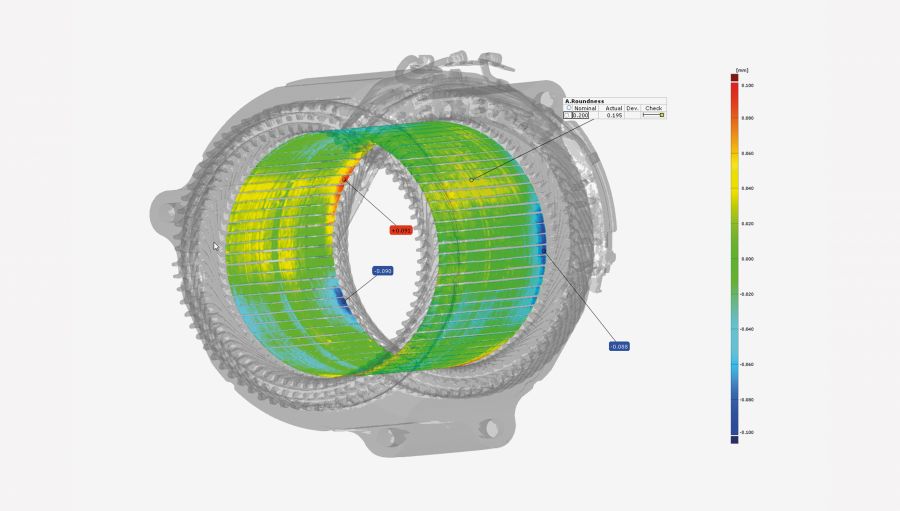

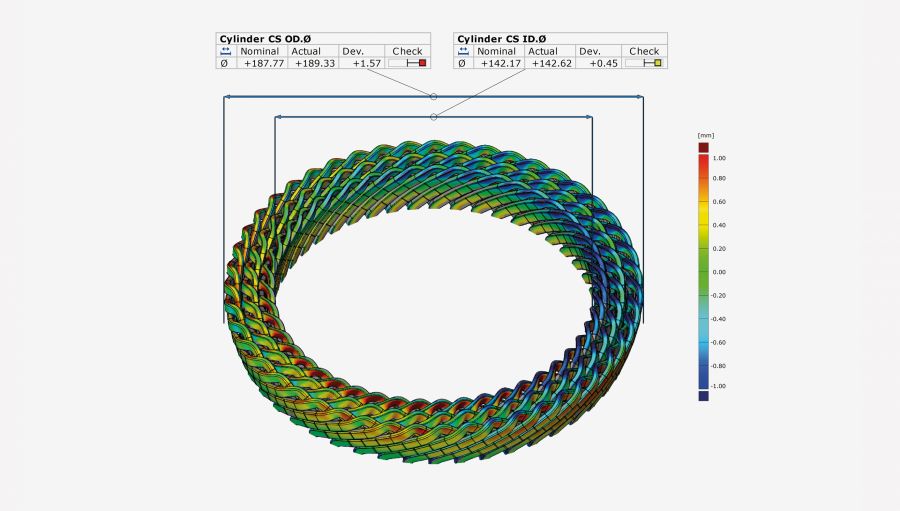

Hairpins and stators: Metrology with high efficiency gains

Manufacturers bend wires into the shape of a hairpin during electric vehicle production. These hairpins consist of a rectangular copper wire and are coated with an insulating layer. The dimensions and positions of such hairpins have to be inspected during stator assembly because they tend to deform very easily and their ends are difficult to weld.

Optical measuring devices are a good solution for hairpin quality control, since the wires are extremely touch-sensitive. What is more, the geometry and position of the hairpins can only be verified with full-field 3D data. ZEISS and manufacturers of electric motors and hairpin stators have been working together in this field for many years. The new ZEISS ScanBox for eMotors is a compact 3D measuring system that has been developed to perform very fast and reliable scans of the hairpins’ highly reflective insulating layer.

The optical 3D measuring machine captures the free-form 3D coordinates of individual hairpins and the entire stator at the click of a button and delivers high-resolution quality information within seconds. The software then displays the results in a clear and easy-to-understand layout.

ZEISS ScanBox for eMotors comes in a package with powerful inspection software for detailed 3D data evaluations.

The software performs complete analysis measurements, e.g. form, angle and position tolerances of hairpins as well as bending points, bending radii and leg lengths.

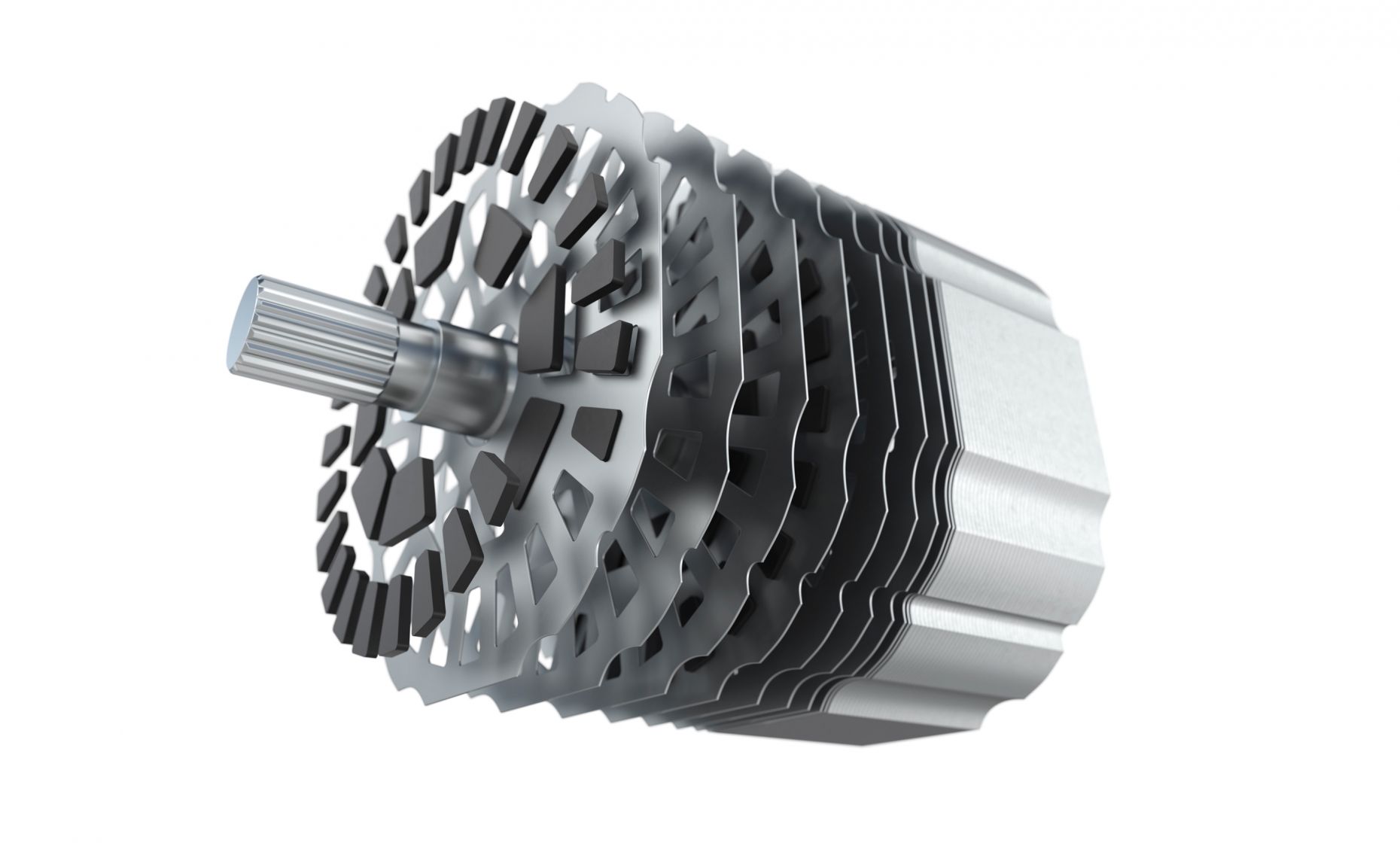

Quality assurance for laminated cores

Stator cores are made up of thin steel laminations. Since tolerances are in the micrometer range, the laminations have to be flat and flashless. Both parameters greatly impact performance of the e-motor, as do the dimension and position of the grooves.

The ZEISS PRISMO multisensor coordinate measuring machine combines tactile and optical sensors into a single system. Thanks to its accuracy of 0,5+L/500 μm (depending on size and model), it is the ideal device for measuring laminated cores. It carries out automated high-speed inspections of component pallets without operator intervention.

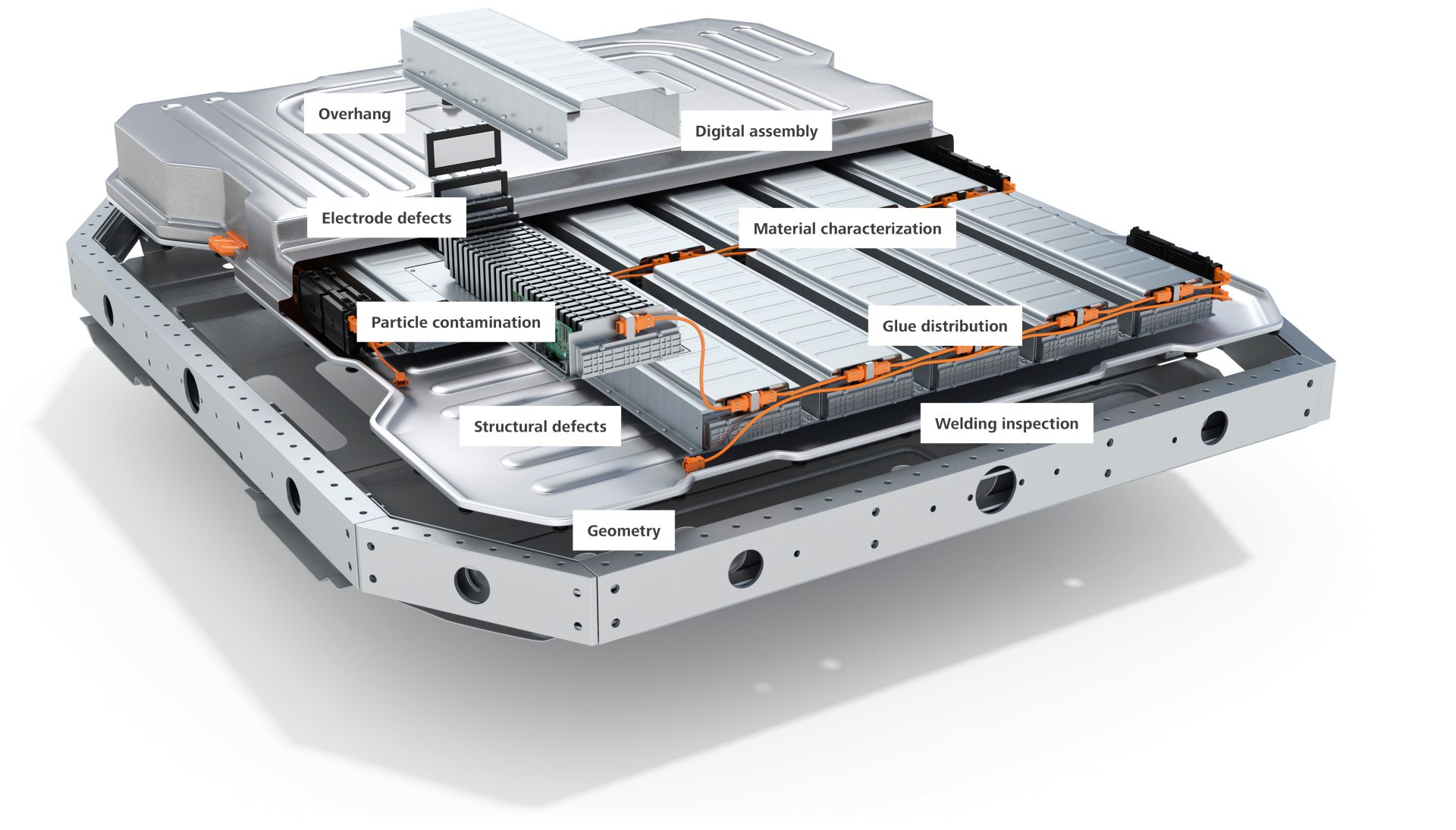

Quality assurance for batteries: Holistic process for all development and production steps

Batteries play an important role in the performance, range and longevity of an electric car. Quality assurance is a complex process: Different measuring techniques are used to inspect battery characteristics, such as material, electrode, cell, module and battery tray.

Industrial microscopy is used to analyze battery materials, cell structures and potential impurities during battery development. The ZEISS Crossbeam scanning electron microscope (SEM), for example, can use an ion beam to expose relevant areas of interest below the surface and analyze them in the nanometer range.

During production, on the other hand, nondestructive analyses are used for battery cells and modules. In this phase, mostly X-ray and computed tomography systems (CT) are employed.

The battery tray – also known as a battery carrier – is another important component that has been fully integrated into the car body and is thus also crucial for its stability. Battery trays have to pass several quality gates during production so as to meet safety requirements and to ensure the quality of the vehicle.

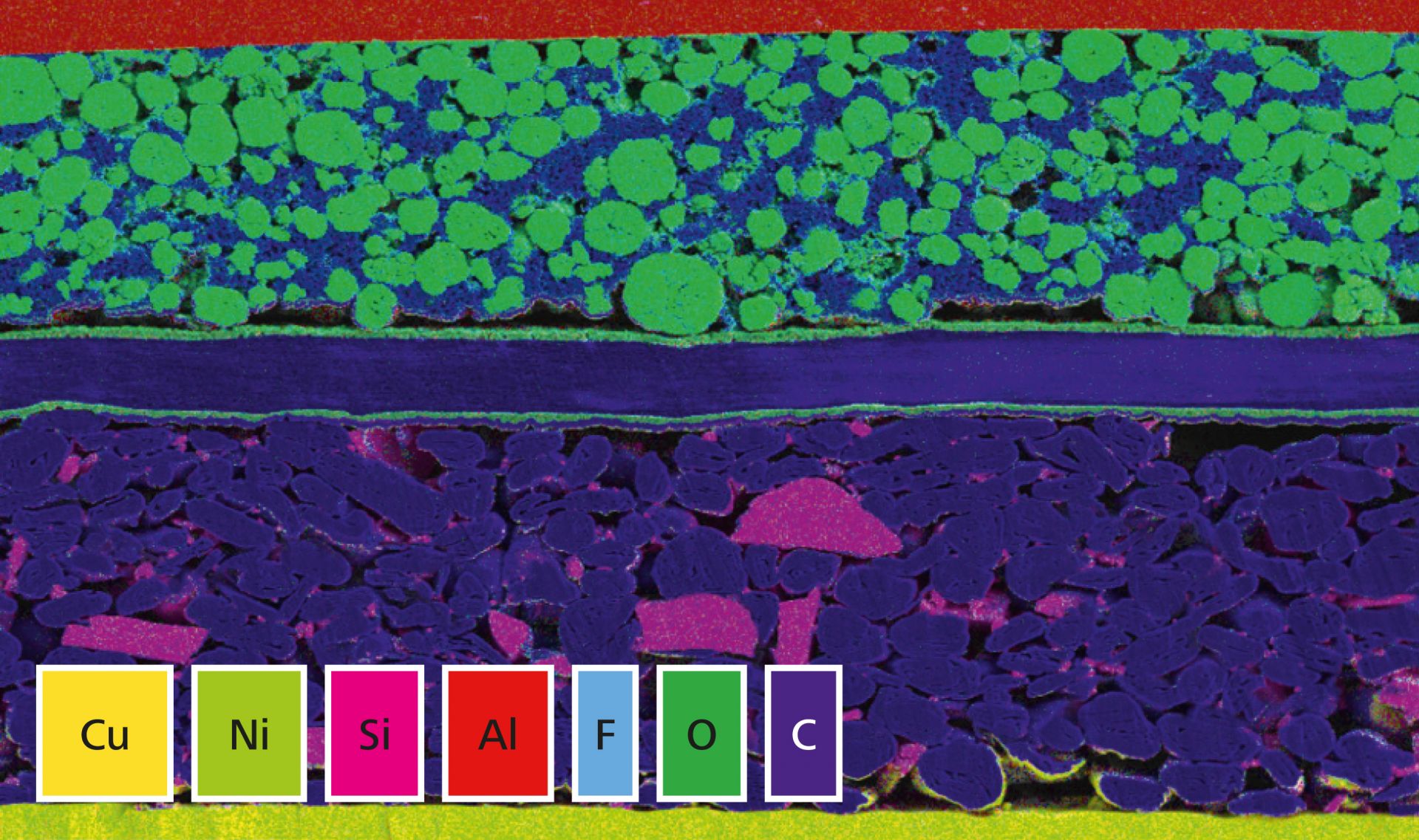

Imaging and material analysis of lithium-ion batteries with ZEISS Microscopy

Complex material systems, such as those found in batteries or solar cells, rely on the interaction of many different materials to function effectively. With the help of energy dispersive spectroscopy (EDS), the elemental composition of the examined objects can be confirmed in the microscope. This image confirms high fluorine residues on the cathode side, as is to be expected in an aged sample.

Fluorine is present in the electrolyte and forms a solid electrolyte interface (SEI), which increases with ageing. Since the recipe of this material cocktail for battery cells is always changing, but also the state of the material distribution after cell ageing allows important conclusions to be drawn, it requires recurring evaluation by material analysis. For example, a steadily growing SEI layer is a finding that explains electrolyte ageing and thus an increased drop in capacity over time.

Computed tomography systems in battery production

In order to meet the demand for NEVs with a higher range, the battery cells’ energy density has to be boosted without increasing their weight and size. This ever-growing density necessitates more sophisticated nondestructive inspections.

CT systems such as ZEISS VoluMax 9 titan and ZEISS METROTOM perform consistent CT scans of dense parts such as battery cells and modules. They generate very high-resolution 3D volume data sets, thus rendering hidden defects and characteristics in dense components, e.g., electrode defects, misalignments, overhangs, housing pores and particle contaminations. The latter are a major safety risk and must not be part of the final product. CT systems efficiently solve complex measurement and inspection tasks with just one scan. This is indispensable for both battery capacity and safety.

With its small footprint, ZEISS VoluMax 9 titan is extremely compact and shows extraordinary robustness. Equipped with a 3k detector, it can scan components measuring up to 590 x 700 mm and weighing as much as 60 kg. Be it in a lab environment or right at the production line, the complete CT solution consisting of a CT system and easy-to-use cross-platform software delivers 3D volume data sets with high resolution, even when scanning large, dense battery modules.

Battery tray inspections

The battery tray is the core part of the body. Its dimensions have a direct impact on the dimensional accuracy and stability of the entire vehicle body. ZEISS offers a unique portfolio for battery tray inspections, including inline and offline metrology as well as aluminum weld seam inspections.

During milling and drilling, many features with tight tolerances have to be measured. The CALENO horizontal-arm machine combines optical and tactile sensors. ZEISS EagleEye rapidly records features such as holes or studs position. Tactile sensors cover optically inaccessible features, such as undercuts, with high precision.

ZEISS ScanBox Series 5 and 6 are used for full-field 3D scans. The optical measuring machines automatically create a geometric digital twin. This is used in the software to carry out full inspections of the relevant features in just a few minutes.