Sustainability

Heading Towards the Future

ZEISS sees sustainability as a driver for innovations that create additional value for its customers, the environment and society.

With 35,000 employees and approximately 100 sites, the ZEISS Group makes an important contribution to sustainable value creation throughout the world. Being a foundation-owned company, ZEISS has ever since been committed to a safe future. This has become an integral part of its corporate identity. The prime goal is to render the company's activities CO₂ neutral by 2025. This complements the goal to convert the power supply at international locations into green energy. ZEISS thus also contributes to significantly reducing global warming to well below 2°C, as set out in the Paris Agreement.

Worldwide

CO2 neutrality

Key target for own operations by 2025

2.6

tons of CO2

Savings through machine retrofit

5.000

tons of CO2

Max. savings with ZEISS AirSaver

As a manufacturer of quality assurance solutions, ZEISS Industrial Quality Solutions supports their customers in meeting their CO₂ reduction targets. When developing new systems, Dr. Marc Wawerla, CEO ZEISS Industrial Quality Solutions, focuses on creating sustainable value for ZEISS and especially on optimizing his customers’ energy balance:

“We want to help our customers to improve their own carbon footprint by reducing scrap through optimized quality solutions and more accurate measurements."

Our three pillars

Circular economy revolving around the future

ZEISS Industrial Quality Solutions focuses not only on reducing water and energy consumption, emissions and waste, but also on a more efficient circular economy that uses green and recycled materials. ZEISS measuring systems, for instance, are designed to last for decades. Selected systems can be retrofitted with state-of-the-art technologies. Refurbishing a machine improves its carbon footprint, since the useful life of the raw material and energy usage is extended.

Innovations save resources

The ZEISS AirSaver, a patented module that reduces compressed air consumption in coordinate measuring machines is a good example of how innovations can save resources. Customers thus save costs and reduce their carbon footprint because, next to power consumption, compressed air generation is one of the main cost and energy drivers in production. With this function, ZEISS contributes to saving up to 5,000 tons of CO₂ emissions by 2025.

Sustainability drives innovations

ZEISS regards sustainability as an important value driver and places its focus on various strategic pillars – throughout the entire value chain over environmental measures down to the common good and social governance.

A shining example

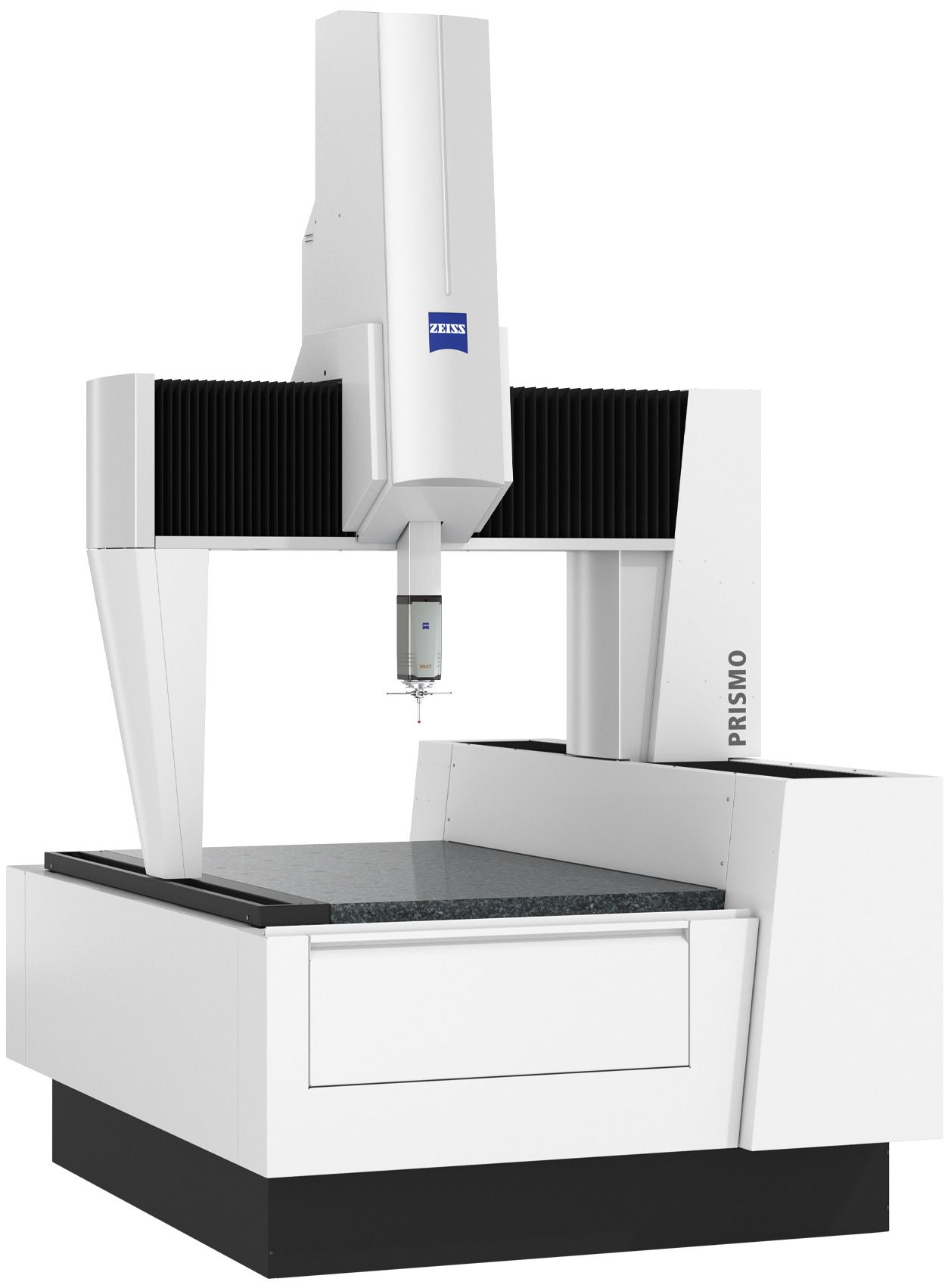

The ZEISS PerformanceFit program retrofits used machines, e.g. bridge-type measuring machines, with new technology.

The useful life of 20-year-old coordinate measuring machines can be extended by at least another 10 years. Large machine components which require high energy input for their manufacture, such as the granite table, the steel underframe or the ceramic bridge, are reused. Approximately 2.6 tons of CO₂ are thus saved for each machine that is retrofitted. ZEISS won the Baden-Wuerttemberg Environmental Technology Award in the category "Material Efficiency" in 2021 for these exemplary efforts.

Not only does ZEISS Industrial Quality Solutions retrofit its customers' machines, it also buys back its own equipment from its customers for a general overhaul and resells it as ZEISS Originals on special terms. In 2019 and 2020 alone, almost 100 tons of granite were saved thanks to that initiative. This way, the carbon footprint of a machine is distributed across several customers.