Connected microscopy

Tiny Worlds, Tremendous Opportunities

ZEISS ZEN core helps you to tap into the full potential of all microscopes.

Industrial microscopy can detect critical impurities or defects on objects and surfaces. The ZEISS ZEN core software suite reveals these details, which are invisible to the human eye. Work simultaneously at several locations with real-time data, generate analyses and reports at the push of a button and enjoy the ease of operation – thus tapping into the full potential of hardware and software.

Oversee everything at a glance: one user interface for all micro- scopy results

The beauty of ZEISS ZEN core is that you can manage the world’s most comprehensive industrial microscopy series in just one user interface. This helps users to improve data exchange and correlation. In the process, data from different devices is merged into a single analysis result. As an example, let us look at quality assurance: No matter whether you check electronic parts or painted car body parts for defects - as a first step, the part always undergoes a visual inspection under the light microscope. Once the defect has been located, the cause analysis starts. And this is where the scanning electron microscope comes in handy with a material analysis or high resolution imaging.

Although the specimen looks entirely different under various microscope types, ZEISS ZEN core is able to relocate a flagged area during the analysis process. Data and images are merged - painstaking searches for the test point across different microscope types are now a thing of the past. The images are automatically overlaid or combined, thus revealing the information. This facilitates collaborative and cross-site work with data.

Microscopy offers a wide range of industrial applications:

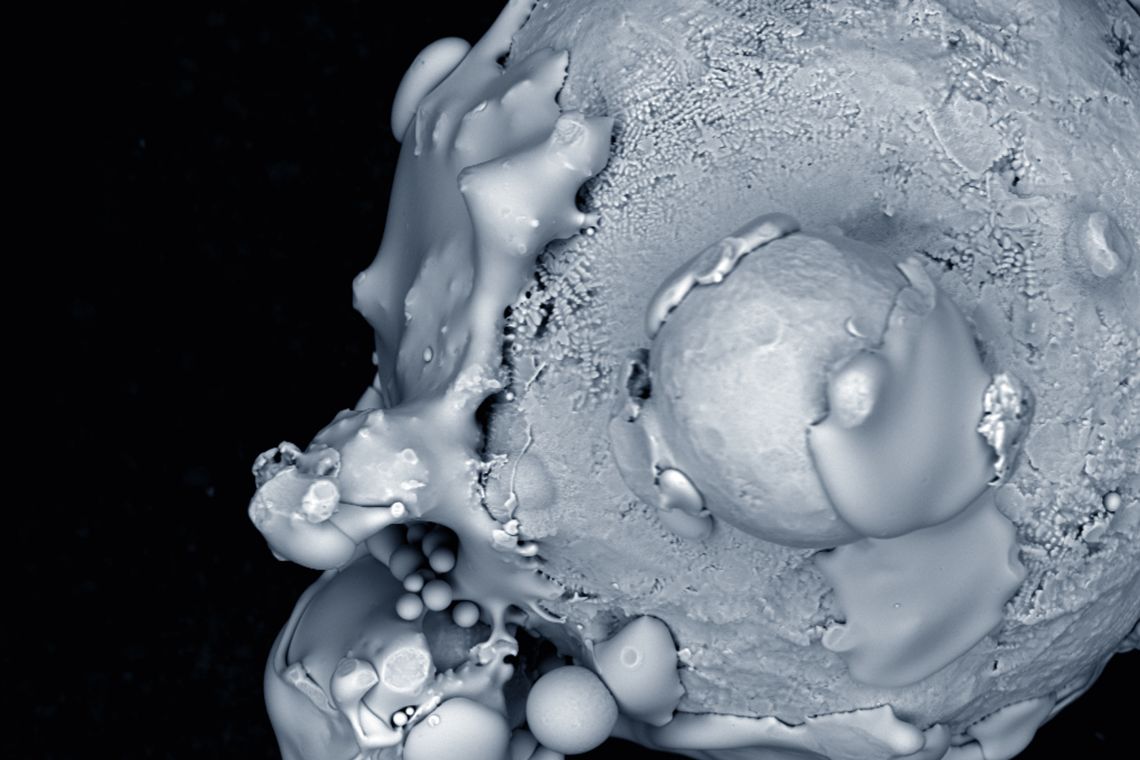

BSE image of pollen in textile structure

inspecting components mounted on a PCB

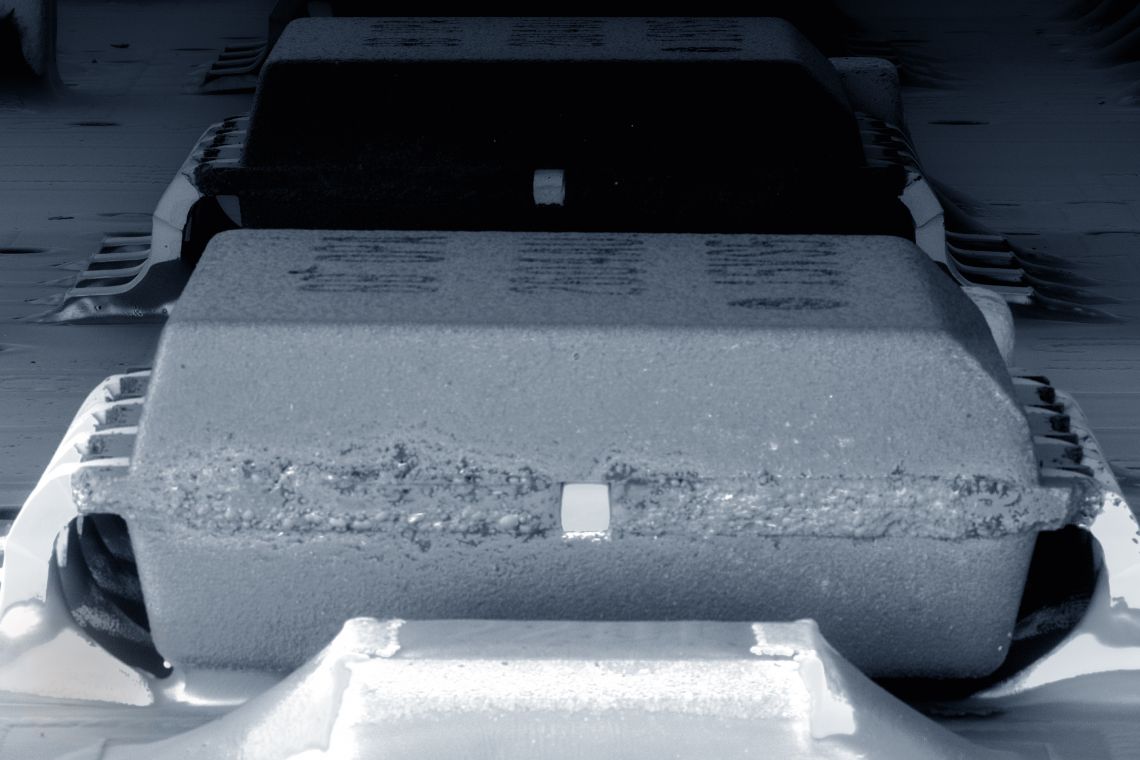

BiCaCo ceramic imaged with BSE detector

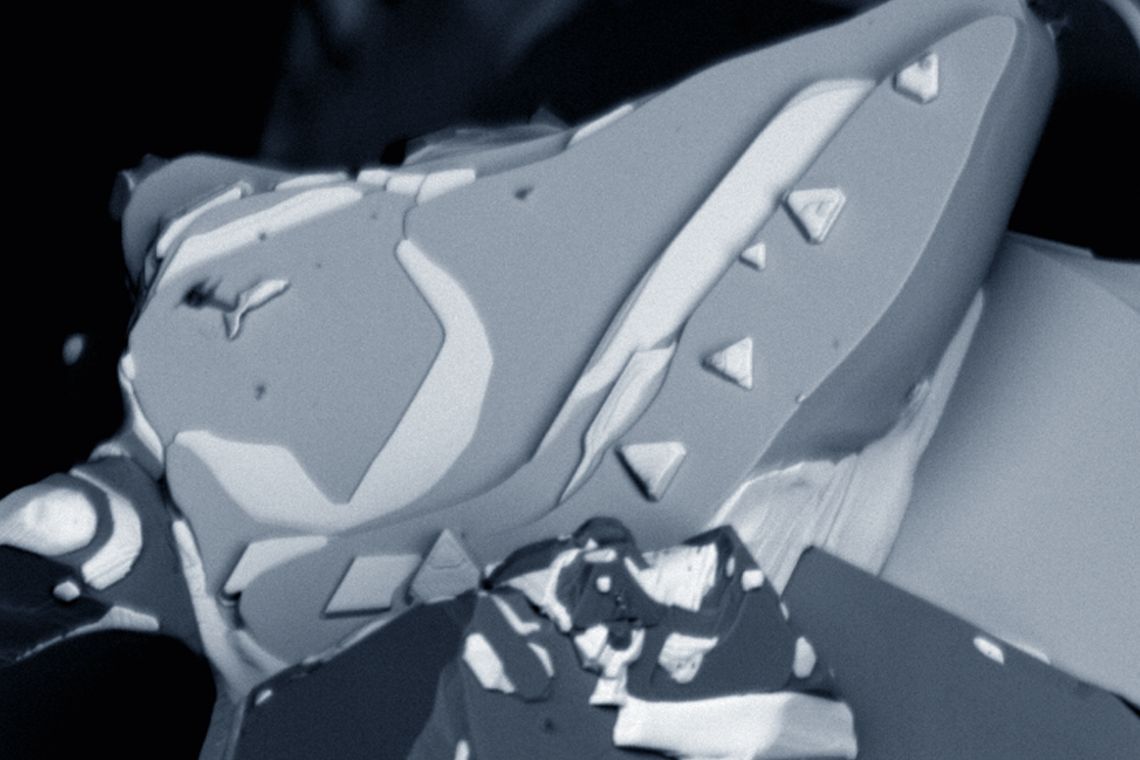

SE image of stellite particle

“At our customers' request, we can now offer fully automated workflows with ZEISS ZEN core.”

Automated microscopy workflows at the push of a button

When workflows are fully automated by using Artificial Intelligence (AI), connectivity and productivity rise to new levels. Automated image acquisition with a AI-supported system to flag interesting areas has already become a standard feature. The AI can segment images – a groundbreaking feature which had to be performed by humans until recently and which can now be automated – including analyses and reporting.

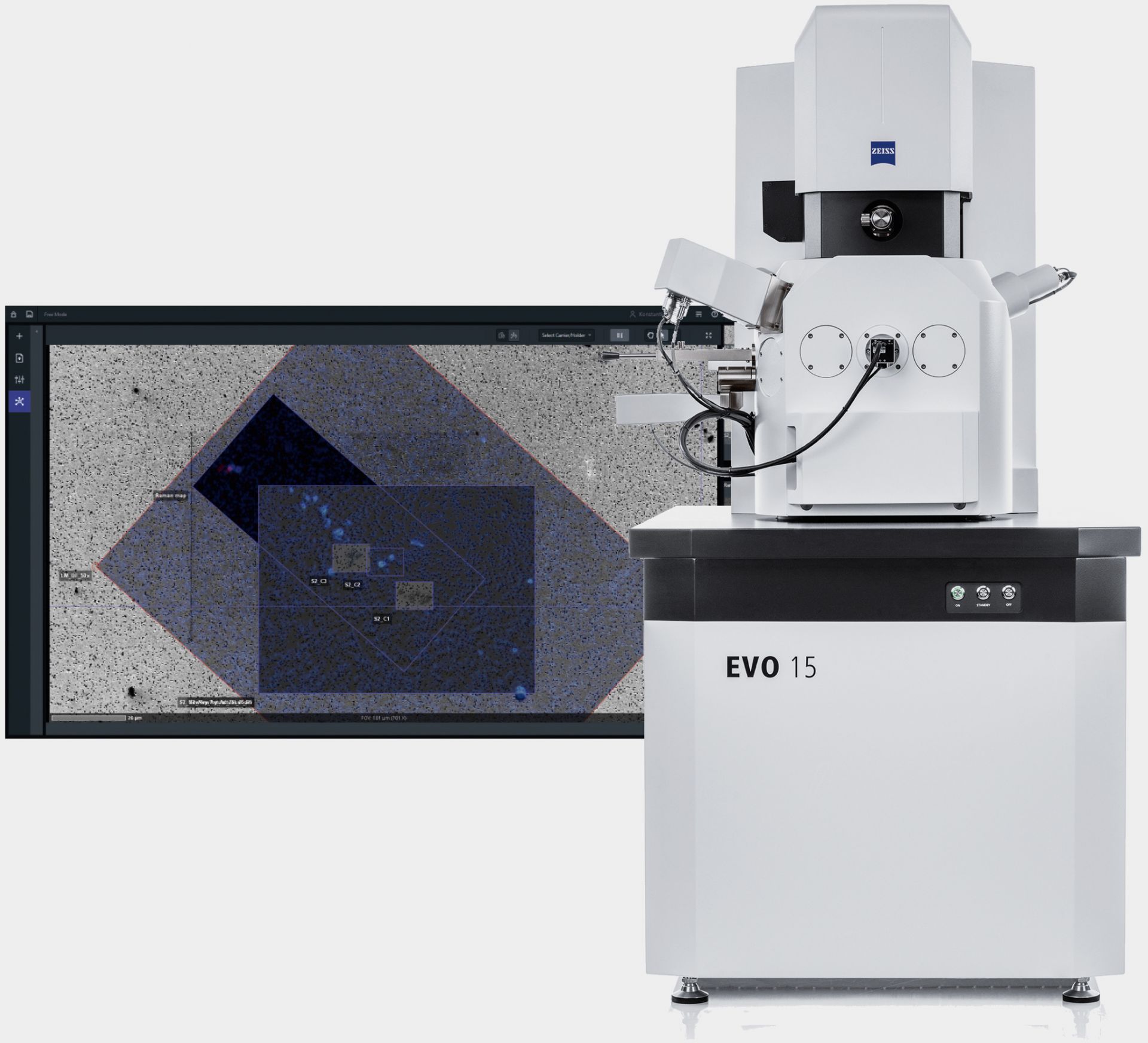

ZEN Connect meets EVO

Correlative workflows with ZEISS ZEN Connect up to the electron microscope

ZEISS EVO electron microscope users can effortlessly integrate correlative microscopy into their workflows and execute automated analyses at a mouseclick. Users can fully utilize the power of their scanning electron microscopes thanks to consistent workflows within the software – intuitively with enormous advantages when it comes to consistency coupled with greater time-saving efficiency.

Learn more here